Heavy-duty stacking and reclaiming system for circular stockyard

Circular gantry scraper stacker and reclaimer is mainly used in

building materials, coal, metallurgy, electric power, port, and

other industries, and is mostly used to stack limestone or coal and

other bulk materials. The cantilever of the stacker is equipped

with a belt conveyor, which passes through the steel structure grid

roof of the circular stockyard from the belt conveyor on the

trestle, and the input materials complete the ring conical stacking

through the belt conveyor on the cantilever of the stacker; The

reclaimer completes the reclaiming work via three linking

processes: traveling system, luffing system, and scraper system.

The scraper reclaimer scrapes the materials into the conical hopper

under the central column along the slope of the pile and outputs

the materials through the vibrating feeder and underground belt

conveyor.

Feature

| product | Stacking and Reclaiming System |

| painting | INTERNATIONAL |

| color | green |

| capacity | 1500 t/h |

| character | heavy duty |

| advantage | robust design |

| benefit | low maintenance |

| material handling | coal or limestone

|

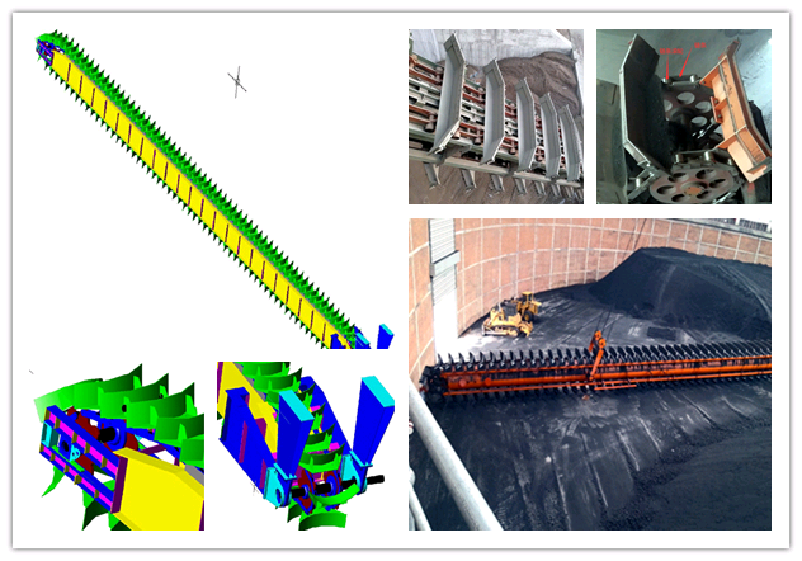

Main components of circular stacker and reclaimer

1. Stacking steel structure, cantilever belt conveyor

The cantilever stacker takes the central column as the center, one

end is the belt conveyor with cantilever steel structure, and the

other end is the counterweight box. The middle stacking slewing

part is connected with the central column by slewing bearing, and

the stacker can rotate by meshing the pinion on the slewing driver

with the gear on the central column. The materials entering the

circular stockyard are unloaded at the head of the cantilever belt

conveyor and directly stacked to the stockyard. The stacker rotates

at a certain angle for slope stacking until it is stacked into an

annular pile.

There are two main structural types of cantilever stacker,

cantilever fixed type and cantilever luffing type.

Comparison of the two types of stackers:

2. King column and slewing mechanism of circular stacker and

reclaimer

The king column of the stacker reclaimer is located in the center

of the circular stockyard. It is an important component of the

stacker reclaimer. It not only bears the load of the main

components and the input trestle but also is the installation

center of the components. Therefore, its manufacturing and

installation process requirements are very high. It is made of

steel plate rolled into a cylindrical shape and welded and

assembled. The utility model is provided with a stacking steel

structure, a rolling bearing for the stacking rotary part, and a

cable drag connecting various equipment components

3. Gantry stacker

The gantry scraper reclaimer is mainly composed of gantry,

traveling mechanism, reclaiming luffing mechanism, and scraper

reclaimer. The gantry is the main component of the rotation,

luffing, and load support of the scraper reclaimer. The scraper

reclaimer is set under the gantry. The luffing mechanism adopts

mechanical winch-type, and one end of the gantry is connected with

the central column by a roller bearing, The other end is supported

on the circular track on the upper part of the stockyard retaining

wall, and the rotation of the reclaimer is driven by the traveling

wheel on the circular track. The gantry reclaimer has a robust

structure, and most of the weight of the gantry is borne by the

retaining wall, which significantly improves the stress state of

the central column and makes the operation more reliable.

4. Reclaimer luffing mechanism:

The luffing mechanism is composed of a driving device, drum

assembly, double steel wire rope, and pitching electrical detection

and control system. The luffing operation of the scraper reclaimer

is completed through the pitching mechanism, to achieve the purpose

of layered reclaiming.

The luffing mechanism uses double steel wire rope single winding,

and the balance mechanism is adopted at the intersection of the two

steel wire ropes to ensure that the stress of the left and right

steel wire ropes is balanced and the work is safer.

The driving device of the luffing mechanism is mechanically driven

by frequency conversion and speed regulation to accurately control

the amplitude variation, to control the change of the reclaiming

amount. To ensure the safety and accurate and reliable positioning

of the pitching mechanism, the driving device adopts a double

braking system

5. Scraper reclaimer

(1) The scraper reclaimer adopts a sprocket to drive the roller

chain, and then the roller chain drives the scraper to reclaim.

This method has large traction, small linear resistance, and

durability. It is a reclaiming method integrating reclaiming and

transportation.

(2)The scraper is fixed on the double chain mechanism, and the

sprocket is driven by the motor at the rear for circular movement.

The scraper scrapes the materials at the lower part of the stacker

into the conical hopper at the lower part of the king column.

6. Hydraulic system

The hydraulic system of stacker reclaimer mainly includes stacker

luffing hydraulic system, scraper chain tensioning hydraulic

system, and belt conveyor manual tensioning hydraulic system

The luffing control hydraulic system is composed of a main pump

motor unit, control valve unit, oil cylinder, oil tank assembly,

hydraulic accessories, and hydraulic pipelines. The pipeline of the

luffing cylinder is equipped with a pipeline rupture safety valve

and a safety valve group.

The tensioning cylinder control hydraulic system is composed of a

pump motor group, control valve group, accumulator, oil cylinder,

oil tank assembly, hydraulic accessories, and hydraulic pipelines.

The tension of the tensioning cylinder can be adjusted by the

corresponding pressure-reducing valve.

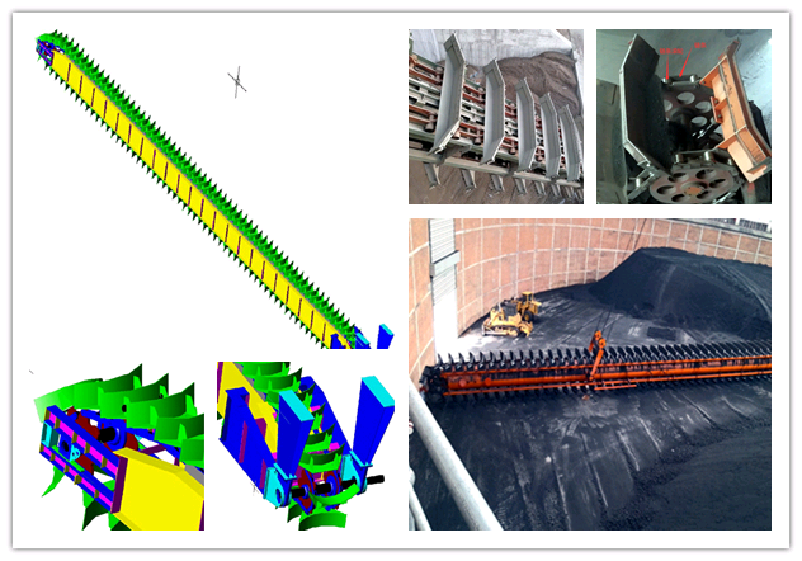

Applicatiions

Case1

Case2