1.Brief Introduction—Bulk material conveying and service

professional supplier

Shanghai Sunshine Industrial Technology is specialized in bulk

material handling equipment, integrator and overseas agent of bulk

material handling. Sunshine Industrial Technology takes the

development of precision manufacturing capacity as its strategic

goal, specializes in manufacturing large and medium-sized precision

parts and reliable bulk material conveying equipment . In addition,

we provide variety of solutions and equipment to clients based on

requirement, including EPC, spare parts, consulting and design

services. Our major product including load and unload equipment

(train tipping machine system, ship unloader, ship loader etc),

conveying equipment (belt conveyor, screw conveyor, bucket conveyor

system, scraper conveyor system, dense phase pneumatic conveying

system), storage equipment (bucket wheel reclaimer, scraper

reclaimer, cranes and all kinds of grab bucket), screen equipment,

auxiliary equipment.

In order to meet the client`s requirement, and provide

comprehensive products and service in bulk material handling. We

had signed a contract with bulk material handling equipment

manufacturer leading company of China Huadian Caofeidian heavy

industry equipment Co., Ltd ,in charge of the overseas market and

project investment of Huadian Caofeidian heavy industry equipment

Co., Ltd;Reaching an agreement in charge of the overseas market of

Liaoning Zhigu mining equipment Co., Ltd ;Zhejiang Xiangshan

Guangming Belt conveyor factory and Wuxi Yixiang machinery Co.,

Ltd.

To be sincere and keep moving, Shanghai Sunshine industrial

technology Co., Ltd always dedicate to high quality products and

service!

2.Organization structure

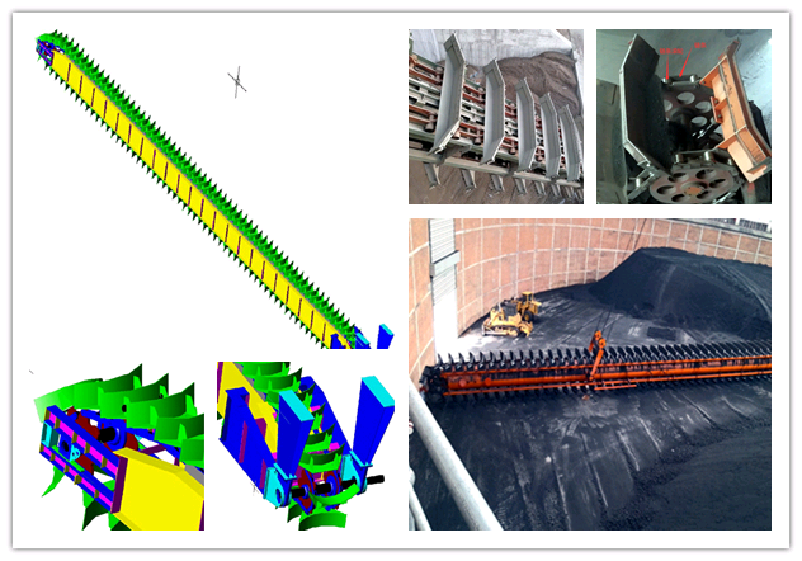

3.Maine product and technical consulting

4.qualification documents

Qualification documents of authorized units in overseas markets

Qualification documents of authorized units in overseas markets

5.Production equipment and facilities

6.Production product display